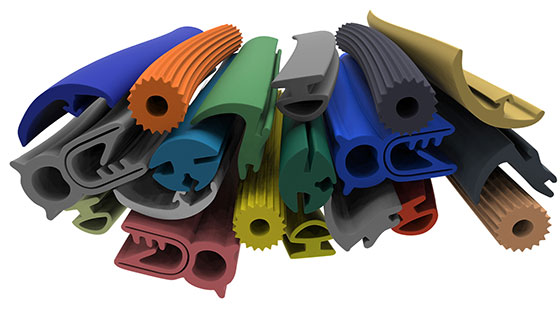

- Extrusion – a continuous process in which plastic is melted in an extruder and then extruded through a tool, shaped and cooled (calibration) to its final form. We specialize in mouldings and profiles in various shapes and materials.

- Post-processing – we can add a variety of value-added features to the products either on the production line or in post-processing. Such methods include, for example, drilling, milling, cutting, marking etc.

- Tool design and manufacturing – the core of all our operations and together are the decisive factor behind the cost and quality of the final product. BS Flex has many years of experience in developing and manufacturing profiling tools.

We have five complete extrusion lines where we can manufacture profile sizes of 1-150mm from high-quality raw materials.

In addition to our competence in the plastic industry, our company also has excellent experience in the planning, design and development of plastic products.

We can help you to implement your ideas.